Every year 92millions of tonnes of waste are produced by the fashion industry. 15% of wasted materials are produced during garment manufacturing. Trying to solve this issue companies now use automatic nesting softwares to gain a few centimeters of fabric but never reaching the 0 waste. The zero-waste pattern making technique eliminates textile waste at the design stage, today no industrial cutting is available for 0 waste designers. We developed a system to allow 0 waste automated cutting.

MAKING GARMENT IS MAKING WASTE, with the zero-waste pattern making technique, we can bring this waste to zero. Unfortunately the impact of this technique is small if we can not access automated industrial production due to instability of the fabric width in the same roll (a roll can be of 25/50 metres and the variation of the fabric width can be of 1 cm). That's why we are working to develop a technology to allow automated cutting, this must be able to:

1. Perceive the variation of the fabric width during industrial cutting meter after meter

2. rethink the pattern placement to adapt to the new width, preserving the zero-waste.

3. Transmit the new pattern placement to the cutting machine in real time.

Indeed, this system involves both hardware and software and needs high expertise in developing a proper solution.

The final commercial objective is not only about scaling up the ZEROBARRACENTO’s production by using this system but also presenting it to brands that are looking for new sustainable strategies to integrate in their daily work. And this market is huge, just to give an example the U.S. sustainability market is projected to reach $150 billion in sales by 2021, according to Nielsen. While the coronavirus pandemic captured the world’s attention in 2020, the climate crisis was also massively destructive, with ramifications including an extended wildfire season in California and tens of thousands of deaths from air pollution and rising temperatures in the United States alone.

The global response to the climate crisis has been muted and insufficient according to international scientists and regulatory agencies, but with revenues and bottom lines at stake, businesses are increasingly changing their ways to adjust for the climate crisis.

Please highlight how the project can be exemplary in this context

Every year 92 millions of tonnes of waste are produced by the fashion industry. 15% of wasted materials are produced during garment manufacturing.

Trying to solve this issue, first of all for economical reasons, textile companies now use automatic nesting softwares which enable them to test hundreds of pattern laying combinations in the shortest period of time. Consequently, they manage to gain a few centimeters of fabric but even with the most powerful algorithms available on the market, we are still far from a full use of materials due to the use of non-complementary curves in conventional patternmaking.

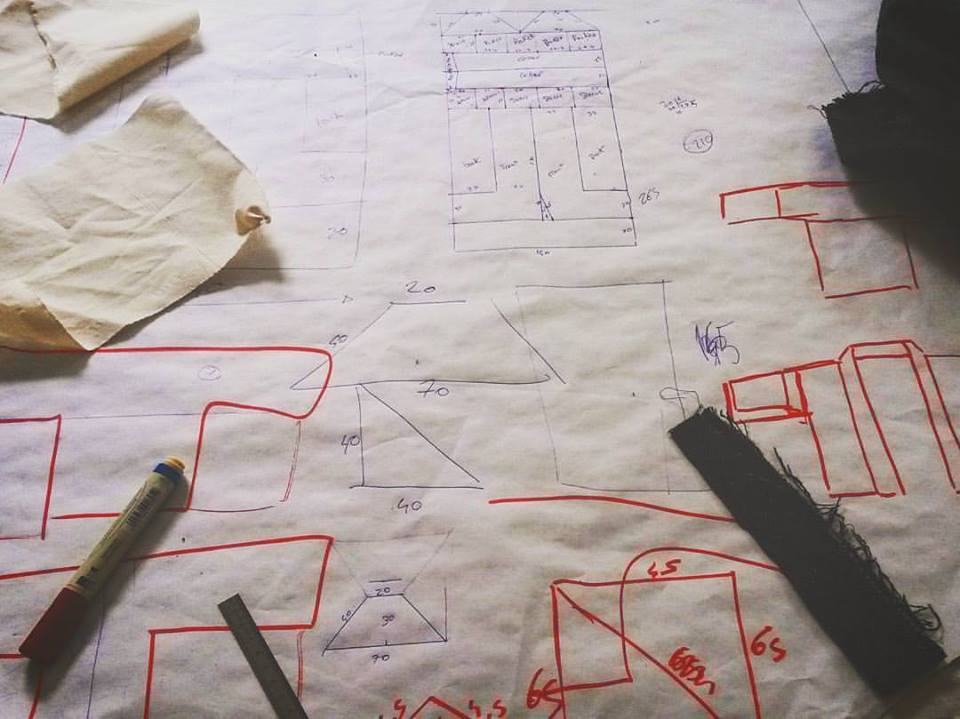

The zero-waste pattern making technique eliminates textile waste at the design stage by creating pieces that perfectly fit in a “sort of puzzle”. In comparison to the conventional pattern making technique, where pieces are designed one by one, zero waste patterns are presented as rectangular blocks which represent directly the fabric used, having clearly in mind width and length of the material.

Unfortunately right now this technique only allows manual cutting. That's why we are working to develop a technology to allow automated cutting, this will allow us to reduce production time and costs, as well as allow scalability of this design strategy.

We decided to work with such an amazing technology provider on the solution, as we definitely have all the experience connected to the pattern making and pattern placement but we were missing the technical expertise needed to develop this system. According to sustainable fashion industry statistics, the market is expected to grow to $9.81 billion in 2025 and $15.17 billion in 2030 at a CAGR of 9.1%.” (The Business Research Company, 2020) The ethical fashion industry is currently worth over $6.35billionUSD, and is predicted to almost triple in a decade. Once our zero-waste system will be ready, we will not only adopt it but we will propose it as “ready to use solution” for major fashion brands, making a real impact.

Please highlight how the project can be exemplary in this context

ZEROBARRACENTO’s expertise is related to zero-waste pattern making and responsible sourcing and will be the guide of this project both defining the objectives and planning and managing the activities as well as testing the outcomes by adopting the developed system in its supply chain. Moreover, ZEROBARRACENTO will define target brands to present the Z.W.A.F.M. to, and prepare a commercial presentation to show the potential of adopting this methodology at best. Zanecom is a young Italian company with professionals with over 40 years of experience in the sector of machinery for the clothing industry. They don't just build machines, they develop innovative solutions and products to provide customers with a technological and functional increase in their company. In this project, they will bring their expertise into the following areas: Numerical control machines for cutting fabrics, Spreading machines, CAD for clothing: drawing and planning, size development, automatic nesting, RFID technology for the management of the cutting room and production processes, Image database management software for quality control and professional product archiving, Technical assistance and professional and qualified consultancy to develop and choose the best solutions for our joint objectives.

Please highlight how the project can be exemplary in this context

According to sustainable fashion industry statistics, the market is expected to grow to $9.81 billion in 2025 and $15.17 billion in 2030 at a CAGR of 9.1%.” (The Business Research Company, 2020) The ethical fashion industry is currently worth over $6.35 billion USD, and is predicted to almost triple in less than a decade. “The growth”, says the report, “is mainly due to the growing awareness about using ethical fashion for sustainability.” Once our zero-waste system will be ready, we will not only adopt it but we will propose it as “ready to use solution” for other major fashion brands, making a real impact on the fashion industry. Nowadays, brands are mainly focusing on sustainable sourcing but there are already companies testing responsible design strategies, and the zero-waste design and production can definitely be their next step. Moreover, we calculated our technology to be ready to be offered to the market at the really competitive price of 150.000,00€, this means that potentially it will be accessible to the majority of companies, this is completely in line with our inclusivity and sustainability dna.

Please highlight how this approach can be exemplary

Zero waste fashion is a new way of design thinking. Instead, it’s a new way of thinking and forces designers to challenge existing techniques. There are generally two strategies for zero-waste fashion: creative pattern making that uses 100% of a given material, and upcycling when you generate garments from remnant materials.

“Zero waste design”, or, “zero waste pattern making,” refers to the practice of designing patterns for clothing with no fabric waste.Technique-wise, it involves fitting all the flat pieces of your clothing pattern like a jigsaw puzzle so no fabric is wasted. Considering that roughly 15 percent of the fabric is discarded when a typical garment is made, the cumulative effect of leaving behind no waste has far-reaching environmental consequences. More than that, zero waste is about working within those constraints to invent beautiful new forms of fashion.

During large-scale apparel production, maximum textile waste is generated during the cutting process. Wasted fabric = wasted money and a wasted planet, and some savvy designers are doing their best to not only reduce garbage in their production cycle but to recycle whatever scraps they may have. ON average, cutting rooms produce at least 15% of fabric leftovers. This solely depends on marker planning and marker efficiency to use every bit of the fabric used. Although many designers have tried to control it through subtraction cutting, geometric cutting, jigsaw cutting, incision cutting, and other techniques, most large-scale factories usually ignore this issue to meet the production deadline and plan fabric cutting with an additional allowance of 3 per cent fabric consumption for wastage. This 3 per cent when equated to millions of garments produced amount to a high quantity of waste.As long as this allowance is ignored, it will keep contributing to give life to enormous quantities of waste worldwide.

According to sustainable fashion industry statistics, the market is expected to grow to $9.81 billion in 2025 and $15.17 billion in 2030 at a CAGR of 9.1%.” (The Business Research Company, 2020) The ethical fashion industry is currently worth over $6.35 billion USD, and is predicted to almost triple in less than a decade. “The growth”, says the report, “is mainly due to the growing awareness about using ethical fashion for sustainability.” Once our zero-waste system will be ready, we will not only adopt it but we will propose it as “ready to use solution” for other major fashion brands, making a real impact on the fashion industry. Nowadays, brands are mainly focusing on sustainable sourcing but there are already companies testing responsible design strategies, and the zero-waste design and production can definitely be their next step. Moreover, we calculated our technology to be ready to be offered to the market at the really competitive price of 150.000,00€, this means that potentially it will be accessible to the majority of companies, this is completely in line with our inclusivity and sustainability dna.

Please also explain the benefits that derived from their involvement.

Our project was born from a real need of the industry. To come to a solution, we had to doo a deep research on both technological providers to understand the market status, garment manufacturers as well as researchers.

Textile waste is clearly a global problem, fast fashion is making it grow day by day. By offering our solution to garment manufacturers and brands all around the world we will optimize the textile and fashion supply chains.

Today brands and manufacturers willing to reach zero waste in their production can either:

1. work with advanced nesting technologies, but never reaching the zero waste

2. work with zero waste pattern making without being able to cut industrially their products.

We will offer a ready to use solution for zero waste industrial cutting.

Please provide clear documentation, communication of methodology and principles in this context.

According to sustainable fashion industry statistics, the market is expected to grow to $9.81 billion in 2025 and $15.17 billion in 2030 at a CAGR of 9.1%.” (The Business Research Company, 2020) The ethical fashion industry is currently worth over $6.35 billion USD, and is predicted to almost triple in less than a decade. “The growth”, says the report, “is mainly due to the growing awareness about using ethical fashion for sustainability.” Once our zero-waste system will be ready, we will not only adopt it but we will propose it as “ready to use solution” for other major fashion brands, making a real impact on the fashion industry. Nowadays, brands are mainly focusing on sustainable sourcing but there are already companies testing responsible design strategies, and the zero-waste design and production can definitely be their next step.

@ZEROBARRACENTO DI CARRARA CAMILLA, 2022

Content licensed to the European Union.