yoona.ai is a scalable AI-based B2B software solution that shortens the design process to a few simple clicks. We are utilising fast processing visual and text data, to generate customer-centric designs out of them. With the integration of AI, 3D and augmented reality tools, ready-to-produce garments and accessories are generated in just minutes.

Intro

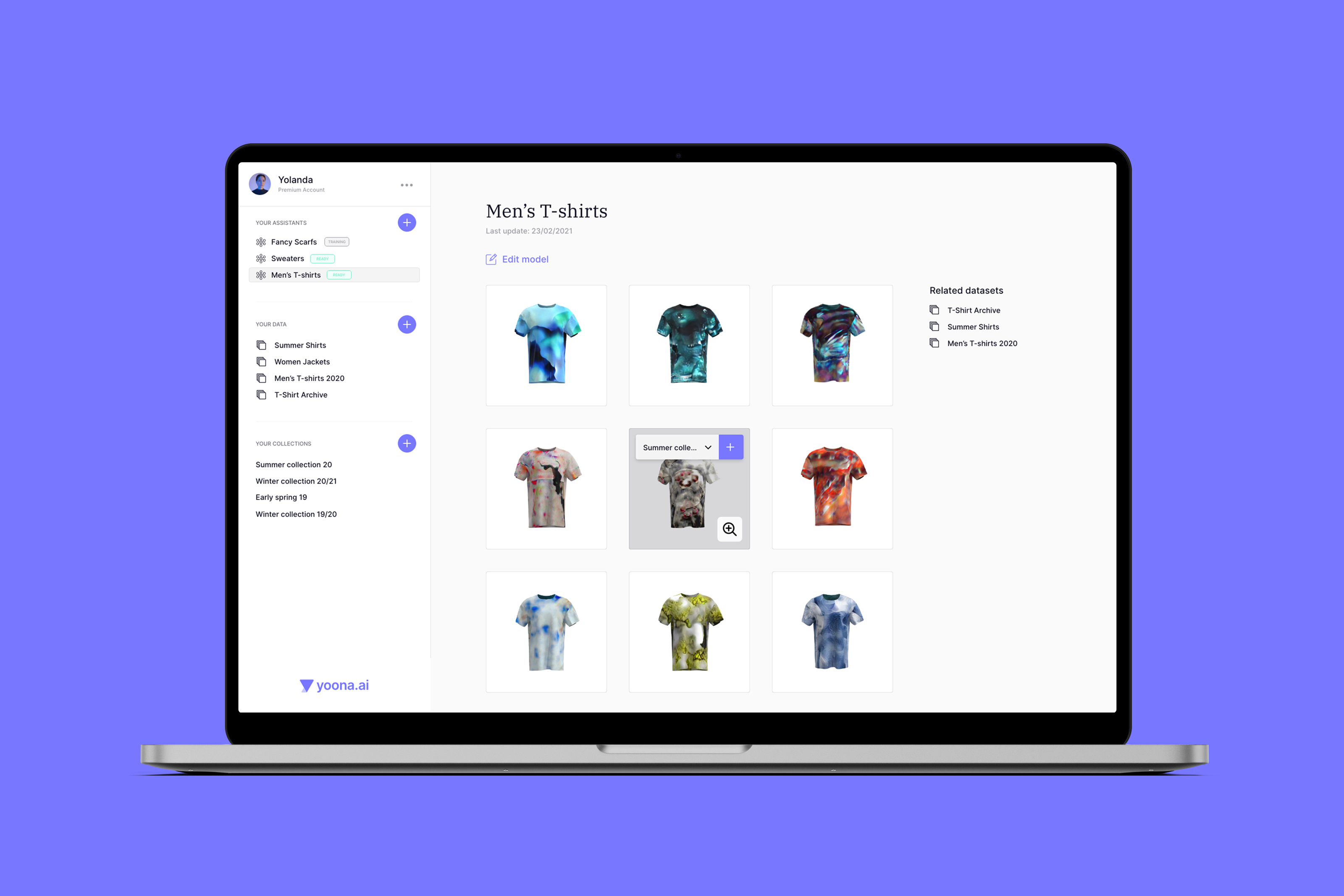

yoona.ai is a scalable AI-based B2B software solution that aims to shorten the design process to a few simple clicks. It does this by utilising fast processing visual and text data, to generate customer-centric designs out of them. With the integration of AI, 3D and augmented reality tools, ready-to-produce garments and accessories are generated in just minutes. Yoona.ai as an analytical tool, aims to shorten the design process to just a few simple clicks.

How it works

YOONA Technology is a SaaS B2B Software Solution created by designers for designers. Companies are looking for their design software with the need to produce items goods faster, at lower costs and satisfy customers' needs. It has a user friendly interface, it’s naitive and easy to operate. The user can upload any kind of data, including own drawings, inspirations, photos, create folders for projects and connect to social media. Just select from the wide range of categories, colors and target groups. It’s convenient and fast, you have everything you need in one page.

3D Design

yoona.ai is known for innovation and each year presents a complete 3D fashion experience in the industry: one of the world‘s first digital fashion shows. All the design outputs through Artificial Intelligence (AI) are demonstrated digitally in 3D to the audience. Resources and materials are saved, new and innovative media are used, and once again, a look into the future is taken.

Please highlight how the project can be exemplary in this context

The fashion industry, as a fundamental part of the textile economy, holds enormous potential in this context. In the following, it will be shown that in the development of collections, the first step in the value chain of the apparel industry sustainability must not only be thought of in an ecological context, but is also accompanied by a substantial economic gain, so that the drive to work sustainably offers advantages on several levels at once. Admittedly, the design process is only one step on the way to the garment. As a first step, however, enormous savings and sustainability potentials can already be realized here. The use of yoona.ai's technology enables companies in the apparel industry to significantly increase their sustainability. This not only makes a fundamental contribution to reducing pollutant and greenhouse emissions, which can enhance brand reputation in the course of ever-increasing market orientation towards sustainable and environmentally friendly clothing production, but also results in major financial savings potential due to significantly lower energy consumption, drastic time savings and significantly higher flexibility in collection development.

Please highlight how the project can be exemplary in this context

The contemporary, modern aesthetic designs realized at yoona.ai using Artificial Intelligence are data-based and created using the latest machine learning trends. The aesthetics of the project are achieved by means of trends, color palettes, as well as experience reports and analyses of the market, own drawings, inspirations and photos which allows to create folders for projects and connect to social media. The customers of yoona.ai create their design based on their preferences and selection of data to be included. This quality-based experience, with the focus on own choice, simplicity of methodology and efficiency, raises the standard of quality that clothing companies can achieve.

Please highlight how the project can be exemplary in this context

The entire yoona.ai team is young, dynamic, multi-national and agile. We come from the global design industry and all have a strong vision and passion to change it and to move towards digitalization and sustainability. Our fashion and tech professionals cumulatively possess 30 years of experience. We have all personally faced all the drawbacks of non-sustainable clothing development and production, and we know how time-consuming and inefficient the process of creating designs without data analytics can be. Thus, we accumulated all our knowledge and passion to create innovation that disrupts the value chain in the fashion industry. Besides the democratic and equal structures yoona.ai is based on, the usage of yoona.ai plattform meets the highest standards when it comes to universal design, accessibility and affordability. Every designer, company and design collaboration can access the platform with no complications from any part of the world. The dynamics of converting clients can be completely achieved online. Accompanied by our customer success manager any question, feedback or help requests can happen in the shortest time possible.

Please highlight how this approach can be exemplary

Sustainability, aesthetics and inclusion are three dimensions without which the use of yoona.ai platform would not be possible; the entire existence of yoona.ai is based on these three significant dimensions. Customers resort to yoona.ai due to environmentally harmful existing design processes in their companies, which in the long run result in high negative output. Designers, most of whom are leaving the industry with burnout, are ultimately given the opportunity to use AI to create designs easily and efficiently, with a focus on aesthetics, and to hire the AI wizards, as intended. This automatically leads to every member in the design industry being able to participate in the platform without walking out with negative consequences, such as inefficiency, burnout, or environmental damage. Thus, the three dimensions form the basis of the yoona.ai experience.

KPIs 2021: yoona.ai is a Techstars portfolio company!

Press Yoona.ai was featured on several national press and magazines platforms. Here you can find a list of our most important article nominations: Textilwirtschaft: «Gerry Weber steigt in KI- basierte Designentwicklung ein» Fashion Street Berlin: «Mit Künstlicher Intelligenz die Krise der Modeindustrie überwinden» Handelsblatt: «Diese Gründerin will mit KI die Modebranche nachhaltiger machen» Next Economy Magazine: Anna-Franziska Michel: „Wir können TESLA für die Fashion Welt werden!“ Project Zukunft Berlin: «Anna Franziska Michel, CEO und Gründerin von YOONA Technology» Startup Valley: «Denke positiv, gut gelaunt und lösungsorientiert!» Berliner Zeitung: «Wie eine Gründerin mit Künstlicher Intelligenz die Modewelt verändern will», Textilwirtschft "TW100, Top 100 sustainability projects 2021"

Panels and Events

Werkstatt der Zukunft 2021: Anna Franziska Michel as speaker during Werkstatt der Zukunft at the Frankfurt Fashion Week. Berlin Fashion Week: Our own panel discussion hosted by our CEO and Oliver Lange from H&M Beyond: "How much Future can Fashion take?" Participation with booth and pitches at SLUSH & Web Summit

Product Improvements:

Higher UI/UX Resolution More Customer Friendly Platform Improved Design Assistant Efficiency State-of-the-art A.I. Design Resolution automated 2D-3D Modeling

Clients and Projects:

Gerry Weber (SMB) VAUDE (SMB) Fraas (SMB) Apart Fashion (SMB) Esther Perbandt (Small) Coen Duetz (Small) Phoebe Heess (Small)

Sales & Business development: Appointments 191 Demos scheduled 55 Won contracts 7 Revenue 46.000,00 Euro Employees: 11

Product: Datasets 76 Amount of data 23.512 created assistants 73 created designs 7815 customer accounts 7 created 3D files 710 API ́s 198 available features 24

Marketing: (January) LinkedIn Search Appearances: (+19%) Page Views:(+85%) Unique Visitors: (49%) Total followers: (+3%) Impressions: (+118%)

Please also explain the benefits that derived from their involvement.

In the department of Business Informatics of HTW Berlin, Anna founded a research group where she came into contact with Artificial Intelligence for the first time. With a total of seven developers, we investigated neural networks and their possible use in the design field. The goal was to shorten design processes and to design closer to the customer. Her results were presented in a collection sponsored by Microsoft “Unter den Linden” in Berlin. With this knowledge of possibilities, she started to build a team uniting garment engineers, machine learning experts, full-stack developers and founded yoona.ai in August 2020. In October 2020, I closed an investment round and in January, Techstars, one of the best American accelerators, invested in our team. Today, yoona is already working with fashion companies such as Gerry Weber, Apart Fashion and Vaude. The city of Berlin had a huge impact on our growth and improvement: The government, University, Berlin Partner, the whole city network is supportive. There are many great funding programs and you can always found the people you meet here in Berlin to be incredibly committed and helpful. Thanks to all our supporters, mentors and fans. We believe yoona is not only Anna, Daniel and the team. Yoona is a huge network and a community which is helping us to succeed.

When I started researching at university for an efficient way of design in the fashion industry, my concentration was on the designers' perspectives, faced with quantities of work that can never be solved efficiently. As yoona.ai grew, it was more and more noticeable how fashion companies are looking for a solution to achieve sustainability and still not lose their profits. The biggest dilemma of the global fashion industry, which is at the root of the unsustainability problem, is the overproduction of clothing quantities and the resulting destruction of unsold goods. We have been increasingly confronted with these major problems that affect the entire world population, since the fashion industry is responsible for 5-10% of CO2 emissions globally.

More than 70% of the footprint from products is determined at the design stage. The fashion industry has mainly a traditional product creation, the whole industry is working in manual processes: manual performance analyses, manual inspiration and trend research, manual changing existing designs, manual changing existing patterns, manual color concepts and manual design creation, manual changing building artworks and motive prints, as well as manual 3D-Design creation. Every year, companies spend more than 55.000 hours on design and spend around 11.000.000 € of their budget on this manual process. This subjective and “driven by hope” methodology leads to designers burnout and more than 5-10% of yearly CO2 emissions globally. In comparison, the yoona.ai design platform is completely digital, automated and based on one-click in every product category. With yoona.ai companies need 1 design hour for a whole collection, only 700.000 € annually to get objective, success- and customer oriented designs that lead to a healthy work life balance for designers to use their creativity wisley. CO2 emissions resulting from the design process via yoona.ai makes only 0,1% of the traditional CO2 emissions resulted by traditional design processes, which lead to 99.8% Energy and CO2 emissions savings.

Please provide clear documentation, communication of methodology and principles in this context.

As a first step, yoona.ai aims to make the design process of any fashion company sustainable and efficient. The sustainability that can be achieved by replacing all traditional design processes of all fashion companies is enormous and promising. Moreover, the technology behind yoona.ai is not limited to fashion design. On the contrary, artificial neural networks can be used to draw conclusions about the design of any product. This knowledge can be applied to a wide range of products that are harmful to the environment, such as the fashion industry. It follows that in the future, using the knowledge and technology behind yoona.ai, any design process can be made sustainable and efficient. In order to draw the attention of companies from the fashion and design industry on digital design processes, yoona.ai has been holding many panel discussions on the topic sustainability in the fashion industry since its founding. The panels mostly take part at fashion shows in different German cities, where the attention of the population is mainly focused on fashion. In addition, the founder of yoona.ai Anna Franziska Michel does monthly PR work related to this topic: through IGTV, podcasts, press articles and online conferences, Anna presents the technology of yoona.ai to a growing audience, as well as important experts in the industry, to raise awareness around the topic. Soon, a collaboration between Telekom AG, H&M and yoona.ai will emerge with the goal of addressing this very topic with its versatility. Through panel discussions, workshops, collaborations with design and fashion students, experts and investors, a broad network on sustainability in fashion will be given with the title: yoonaverse - the data lab connecting dots between circularity and technology. Internationally, yoona.ai was presented through it’s co-founders Anna Franziska Michel and Daniel Manzke on various important stages in different cities: Milan, Lisbon, Dubai, Helsinki, Frankfurt und Berlin.

Energy saving

Worldwide, approx. 120 billion items of clothing will be produced in 2021. 10% of these will come from Germany, making 12 billion garments.

In Germany per year approx. 22,000 TJ energy consumption of the clothing industry. This results in an energy consumption of approx. 1,833,333 J per garment. In other words, 1833 kJ.

This amount of energy is roughly equivalent to 0.51 kWh. For the 24,000 shirts, this results in an energy consumption of 12,240 kWh. Yoona needs 300W x 48h = 14.4kWh (training phase) + 300W x 0.5h = 0.15kWh for this process, so a total of 14.54kWh.

Savings: 12.225kWh, or 99.8%.

For sweatshirts, pants and other larger garments, the savings are naturally much greater.

CO2 savings

The textile industry produces about 1.2 billion tons of CO₂ emissions annually, significantly exceeding the combined emissions of international aviation and shipping. The emissions are equivalent to about 5% of global CO2 emissions.

According to research by the Massachusetts Institutes of Technology, a CO2 equivalent of about 5.5 kg for a synthetic shirt and about 2.1 kg for a cotton shirt could be calculated.

Large companies have an average of about 6000 designs developed each year. In this context, about 4 prototypes are created per design. This results in about 24,000 prototypes produced, so that for these companies a CO2 production of about 52.8 t for a cotton T-shirt and 132 t for synthetic shirts can be calculated.

In the context of a collection development, the use of yoona.ai technology results in significantly lower emission levels, since the complete digitalization of the process means that there is no need for physical pre-products.

Cotton 52,800kg

Synthetics 132,000kg

Yoona total 8.96kg

Savings:

Cotton 99.98%

Synthetics 99.99%

@yoona.ai , 2020

Content licensed to the European Union.