re:Mix is a kitchen mixer that blends smoothies, sauces, soups, nut butters, coffee, desserts or even cocktails. It’s fun to use, as you’re creating recipes directly in the canning jars you have at home. It is designed to be loved, repaired and upgraded forever. It fits your style and kitchen by being customizable. It is made ethically and locally in Berlin, and open-source.

From July to December 2021, we took part in an accelerator for the circular economy called "Better Together", run by the Impact HUB Berlin. The funds from the European Social Fund were channelled by the Berlin senate to the local level.

We are a Berlin-based tech company making circular home electronics products that are good for people and the planet. Having experienced the frustration of kitchen mixers breaking within less than 12 months from purchase, we found that there are no sustainable, long-lasting alternatives for kitchen mixers and appliances at a decent price.

re:Mix is a kitchen mixer that makes smoothies, sauces, soups, nut butters, desserts and cocktails. It is practical to use, as recipes are made directly in the glass canning jars people have at home. It is designed to last, be repaired and upgraded forever. Its materials and colours are customizable to fit one’s taste, and it is made ethically and locally in Berlin.

re:Mix is sustainable - from its modular design, to the choice of durable and recycled materials, to the use of standard components, to prolonging the product lifetime through digital passports and on-demand 3D printed parts.

re:Mix is an object of desire - from using modularity and recycled plastics to create an aesthetic look, to enhancing the experience of preparing meals and drinks - by creating recipes directly in the canning jars you have at home.

re:Mix is inclusive - from producing in social centres in Berlin, to empowering users to DIY-repair their devices, to publishing it open-source to be replicated around the globe.

We have designed and built fully-working re:Mix devices, have tested them with users, and are currently preparing a crowdfunding campaign, to fund our first production batch.

We believe re:Mix is a pinnacle of circular design, which beautifully illustrates how the values of sustainability, aesthetics and inclusion are reinforcing themselves when applied together. By encouraging modularity and open-source practices, we hope to enable a system of decentralised production based on locally repaired, reused and recycled materials. Run on renewable energy, this system loops sustainably, and brings together users, producers, and communities.

Please highlight how the project can be exemplary in this context

We aim for sustainability at 3 levels: product, digital, and business. By increasing product lifetime fivefold - from the current average of 11 years to 55, only a fifth as many products will be needed - saving resources and emissions.

On a product level, our objectives were:

- A modular design that allows for quick assembly, disassembly, upgrading and repair using common tools, without the use of harmful adhesives and expensive industrial machinery. Strategies used are puzzle-like connections, a simplified design to allow for e.g. blade replacement, choosing a motor with replaceable brushes, using standard industry parts (e.g. a knob).

- Using only durable, healthy and largely recycled materials

- Compatibility with glass canning jars, giving these a new life.

- Regional sourcing, as far as possible. The outer casing is made out of 100% recycled, regional, post-consumer plastics.

- Local assembly in Berlin, minimising transportation emissions

- Built-in lifecycle thinking for its components, foreseeing their repurposing into other electronic products (e.g. speaker, light, toaster) - as part of the larger open design system we are building

- In the next few years, we will switch completely to local, reused parts (motors, cables, switches)

On a digital level, our objectives were:

- Creating an easy way for users to get access to further services, by placing a QR code at the back of the device

- Being transparent about what the product is made of and who made it, by using a digital passport

- Making DIY-repair and ordering spare parts frictionless via guided videos and virtual assembly sessions.

On a business level, our objectives were:

- Designing components that are open-source and are easy to reproduce locally, on-demand, and 3D printed.

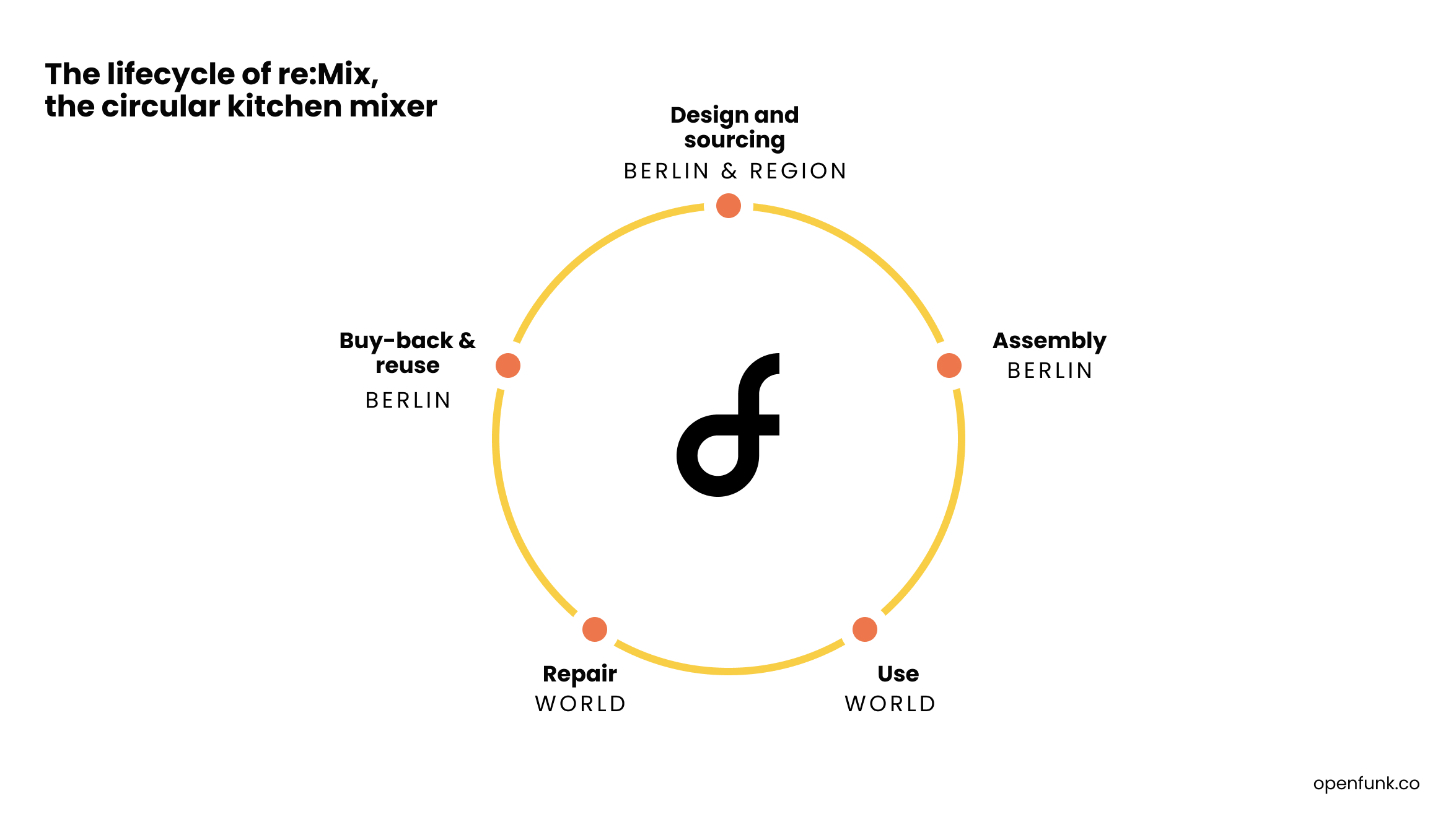

- Keeping products in the loop by setting up a buy-back scheme. When the mixers are no longer needed, we buy them back, refurbish them and sell them again as refurbished goods.

- Finding regional, reliable partners

Please highlight how the project can be exemplary in this context

With re:Mix, we aimed for a device which is not only sustainable, but which is aesthetically pleasing and that provides an enhanced user experience.

re:Mix tells its story just by looking at it. We leveraged upon its modular construction to give a high-quality, durable, timeless feel that reflects the way the device is built. The front-and-back recycled plastic panels contain visible, colourful particles which not only stand out from mainstream devices seen in the kitchen, but also visually communicate the flow of materials which went into the creation of the device. The thick panels and hard edges are aesthetically pleasing, but they are also functional - sound-proof, sturdy and allowing for a puzzle-like construction without glues.

But re:mix needs to be used in real life to fully grasp the way it brings joy to the kitchen. People are generally attached to their glass jars which they have in their kitchens. They are beautiful, transparent, come in different shapes and sizes, and are pleasant upon touch. Users can use these beloved objects directly with re:Mix. When they are done mixing, the serving doesn’t have to be transferred to another glass - it is already in the preferred container: so it can be used for serving on the table, storing in the fridge, or for taking it on-the-go. Directly using these jars for consumption means there is no need to clean multiple containers.

Furthermore, we designed re:Mix to replace multiple devices: smoothie-maker, nut-butter-maker, sauce-maker, and coffee-grinder. It comes with powerful motor that can crush anything up to nuts and ice. By using jars of different sizes, users can adapt the jar sizes to fit the food/drink they are preparing, e.g. a small jar for sauces.

An easily accessible QR code at the back of the device enhances the user experience by giving users access to our community section, inspirational recipes, product care and repair guides, and swappable accessories and blades (e.g. for grinding coffee)

Please highlight how the project can be exemplary in this context

We aimed for inclusivity by combining a number of elements:

- Producing locally. When products are made locally, for the local market, there is a natural tendency toward jobs with dignity. Producers are more trustworthy, more easy to verify, and simply more responsible towards their own community.

- Producing ethically. re:Mix is assembled in a social centre in Berlin, which is dedicated to the social participation and professional inclusion of people with disabilities. This is a stark contrast to the typical production in Asian countries, which have a spotty track record which includes child labour, worker exploitation, poor social support, and long working hours.

- Educating users via DIY-repair. Instead of buying new goods, our users engage with the construction and functioning of their device. Repairing a device makes one understand not only how the device functions, but also to appreciate the complexity and valuable resources contained in them.

- Connecting users with assembly workers. Via a QR code at the back of the deivce, users can see exactly who built their product, tip that person, and even exchange small, gratifying texts and images. This is rewarding for users, but also for the assembly workers, who can proudly see what their work eventually contributes to.

- Making design files accessible via open-source. We make the designs and production processes of re:Mix open-source, so that others can replicate and improve upon our design in their own communities. This makes repairs of our products and the offering of spare parts easy, but it also enables hobbyists or other entrepreneurs to build electronic goods in their localities. Furthermore, open-source means there is no need to reinvent the wheel every time, which encourages standardisation of parts and universal design and practices. To make replication of our devices globally accessible and possible, parts have been designed so that they can be reproduced locally with basic workshop tools.

Please highlight how this approach can be exemplary

By combining these principles, re:Mix is not only sustainable, but that also improves the product experience at every level, and is aesthetically pleasing. It is an object of desire, which people want to have because it makes their lives easier. Furthermore, it integrates the latest technologies in local manufacturing and digital services to enhance the user experience, and prolong the product lifetime. Much as Tesla has become the electric car people want to have, we hope to make re:Mix their mixer of choice.

At the same time, we are drastically raising the bar on sustainability standards in the industry, as well as setting the groundwork for a more inclusive, local, community-oriented system. We hope to nudge the industry towards more sustainable practices, much as Fairphone challenged the smartphone industry.

We are excited to see how others take our modular design system and apply it to different contexts, locations, cultures, and products.Furthermore, being open about how re:mix is built and by making DIY-repair accessible and simple, we hope to educate, inspire and inform people about what goes into their products, and promote life-cycle thinking.

We managed to design and build a device that is not only sustainable, but that is also desirable. While re:Mix cannot be ordered yet, we have received outstanding feedback on its aesthetics, functionality and overall approach. We currently have a waitlist of 300 users, and will soon be launching our crowdfunding campaign. At the fairs we attended, roughly 80% of the people passing by would add themselves to the waitlist.

re:Mix is fully disassemblable, repairable and upgradable via do-it-yourself methods, with no glues and only a screwdriver needed. Enhanced by services such as product passport, guided DIY-repairs and buy-back schemes, we hope to prolong fivefold the lifetime of mixers - from currently 11 years on average, to 55.

Furthermore, we validated the feasibility of producing locally at an affordable price, found the local partners needed for R&D, production, repair and refurbishment, and validated the designs by world-renown circularity designer Tapani Jokinen.

Please also explain the benefits that derived from their involvement.

As experienced designers, we know how important early user involvement is. The current products are a result of an exchange with over 30 people during early product development between January and July 2021, and more intense co-creation and testing sessions with 30 potential users. We “build in public” via Instagram, asking our audience for feedback on different designs and ideas.

We have attended fairs (Zero Waste Festival Berlin, Green Market Berlin, Motion Lab) and organised “smoothie-sessions” (Impact HUB Berlin, Motion Lab Berlin), with the goal of collecting user feedback on our prototypes, as well as on various business aspects.

And we have engaged with Open Knowledge Foundation Germany in a collaborative event where we shared our experiences and struggles, while receiving advice on open-source hardware.

As part of the Circular Together Accelerator 2021, we have engaged with experts ranging from the fields of finance to legal, and from marketing to business modelling. This expert feedback allowed us to verify assumptions and gain knowledge we lacked. Furthermore, we are having bi-weekly meetings on design and circularity with Tapani Jokinen, a strategic and circular design consultant with 25 years of experience, author of the Ecodesign Learning Factory from the Fraunhofer Institute, and former head of design and strategy for mobile phones at Nokia, under which the durable Nokia 3310 was designed.

All this feedback has flown iteratively into the design of re:Mix, and of our business.

re:Mix is a single device, but it lays the groundwork for an open design system of parts and components for home electronics. What emerges is a system of decentralised production based on locally repaired, reused and recycled materials. Run on renewable energy, this system loops sustainably, and brings together users, producers, repairers and communities. It’s a great win for people and the planet altogether.

E-waste is the fastest growing waste stream globally, according to the United Nations, increasing by 21% to 53.6 million tonnes between 2014 and 2019. Europe ranks first in the world with 16.2 kg of e-waste per capita per year. E-waste poses a threat to health and the environment as it contains toxic additives or hazardous substances such as mercury that damage the human brain and/or coordination system. Less than a fifth of it is recycled. The main reasons mentioned for the rapid growth are the higher consumption of electrical and electronic devices, the short life cycles and the few repair options.

Our experience from dismantling several dozen mixers has shown that current products break easily, are not designed for dismantling and longevity, and their spare parts are difficult to obtain, often making repair or dismantling impossible or very expensive. Material extraction and production often take place under non-transparent conditions, with child labour, health issues and exploitation regularly emerging as problems.

Furthermore, people with disabilities are often marginalised in societies across the globe. Assembly processes provide suitable jobs, which can be adapted to the ability of the individual. This creates a career path and a much-needed environment for social interaction, empowering individuals.

That is why we have chosen to design products from scratch: so that we have full control over how they are designed, but also how and by whom they are made, thus making a positive environmental and social impact. These are all activities which can happen locally, decentrally, with by harnessing the power of modularity and open-source,

Standard industry practices are geared towards competition and winner-takes-all. In contrast, our approach encourages collaboration and win-win situations, where we strive for a shared goal: creating a system for ethical home electronics that works within planetary bounderies. See the attached deck for a comparison between re:Mix and industry players.

At a time where home electronics companies label themselves sustainable merely for increasing the amount of recycled content in their products, re:Mix is designed from the onset using state-of-the-art circular practices in terms of modularity, repair, material selection, and supply chain transparency. At the same time, it improves the overall experience - thanks to the ready-to-eat system with glass jars and digital services - and utilises design and materials to create a desirable, timeless look.

Most mixers are made in faraway countries in Asia. They are made in spotty working conditions and then shipped across the planet, with no design intention of repair or reuse. In this context, repair options are few, and the quality of parts is going down - as well as the product lifetime. By producing in an ethical production facility in Berlin, we have transparency over the conditions in which re:Mix is made. Furthermore, the emissions from moving parts around, as well as shipping, are lowered. Users can DIY-repair their devices by following our video guides, or send it back to our facility in Berlin for professional repair.

While companies fight for patents, blocking collaboration at a global scale, our approach uses the power of open-source to decentralise the production system, empowering local communities. The components of re:Mix can be locally reproduced and sourced from used devices, which means spare parts availability is not dependent on our success. We hope to spur a never-before seen collaboration between users, recyclers, repairers and manufacturers, as they keep their products in the loop.

Please provide clear documentation, communication of methodology and principles in this context.

We are called Open Funk because we are open at our core. This means openly sharing what we do, using open standards, and publishing open-source. Our success is tied to the success of others being able to replicate our processes and products around the globe.

On our social media channels, we are openly publishing about our progress, and challenges. We recently started a blog, which we will use to describe more in detail certain aspects about our products and processes. Furthermore, users will be able to share, exchange and learn from each other - from getting creative in the kitchen, to repairing their products, to making creative “hacks” to their products, to replicating and building the devices and adapting them to the local needs.

We will use GitHub as the central place for sharing our design files, and complement that with easy-to-understand videos with repair and built-it-yourself instructions. To do that effectively, we are in close collaboration with Open Source Ecology Germany e.V. and Open Knowledge Foundation e.V.

Furthermore, as part of our crowdfunding campaign, we are offering built-it-yourself workshops, where we invite users to build the devices they have ordered, together with us.

Our ultimate goal here is enabling other makers, companies and producers to incorporate our practices into their products, thus forming a global design system that is repairable and modular - as well as educating users about repair and how they are built.

This deck shows a live demo of re:Mix, how it works, material and color customization, and a demo of the digital platform.

@Open Funk UG, 2022

Content licensed to the European Union.