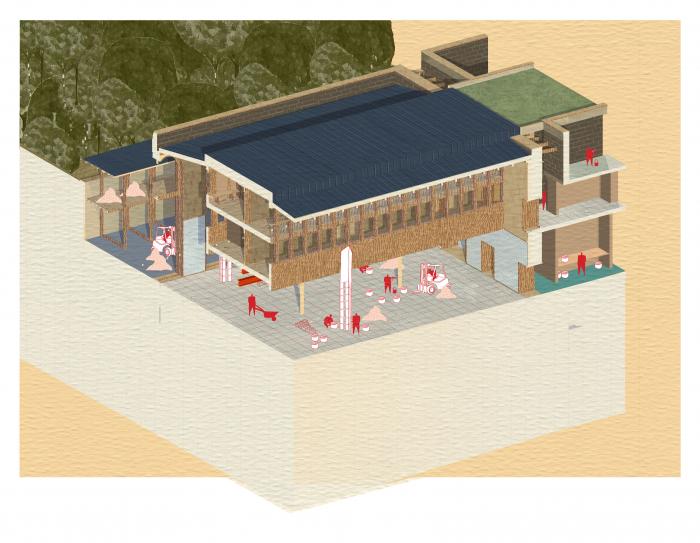

The « Architecture Center for regenerative materials » is thought as an eco-system, a place to experiment, raise awareness and produce around regenerative materials. Firstly, the « Micro-Factory » is a producing place where insulated growing mycelium-based panels are produced on its basements. Growing panels drive us on a post-carbonated direction for construction. Secondly, the « Macro-Factory » is thought as a big experimenting room, where could be built 1/1 scale prototypes.

The « Architecture Center for regenerative materials » is thought as an eco-system, a place to experiment, raise awareness and produce around the regenerative materials. We propose, as a first step, to substitute industrial materials by, as much as possible, natural materials, which require less carbon during their production.

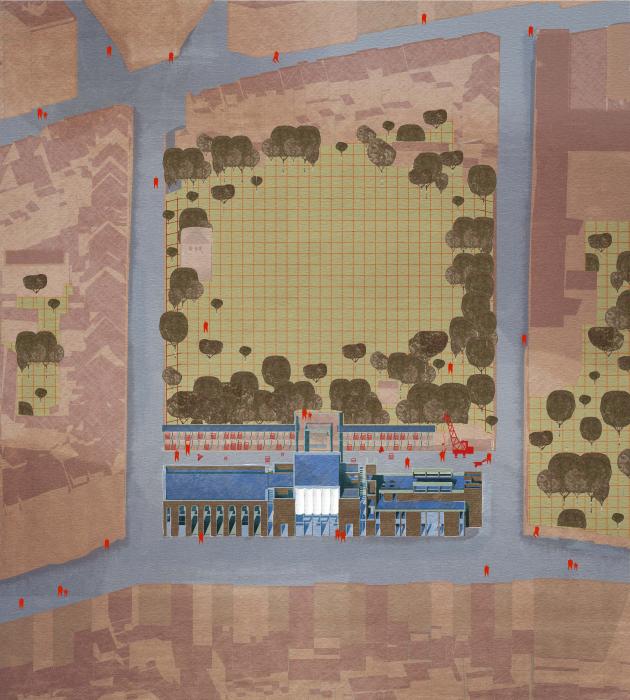

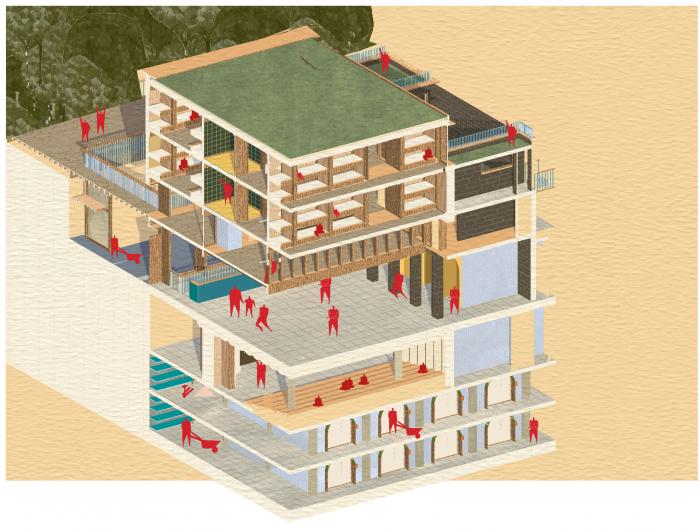

The building is divided into three parts. Firstly, the « Micro-Factory » is a producing place where insulated growing mycelium-based panels are produced on its basements. Growing panels drive us on a post-carbonated direction for construction, facing both the reduction on the use of raw materials and the thermical renovation issue, while transforming empty floors in producing places. The overhaul of construction production methods must accompany a broader agricultural policy, on a national or even transnational scale, with the North of France and the Netherlands. As a congested European metropolis, integrated into the network of the European megalopolis, Brussels is dependent on supply circuits for raw and, above all, processed materials. We would suggest that the metropolitan area could accommodate production sites for materials based on plant fibers and mycelium, in order to be able to supply the entire built fabric of Brussels.

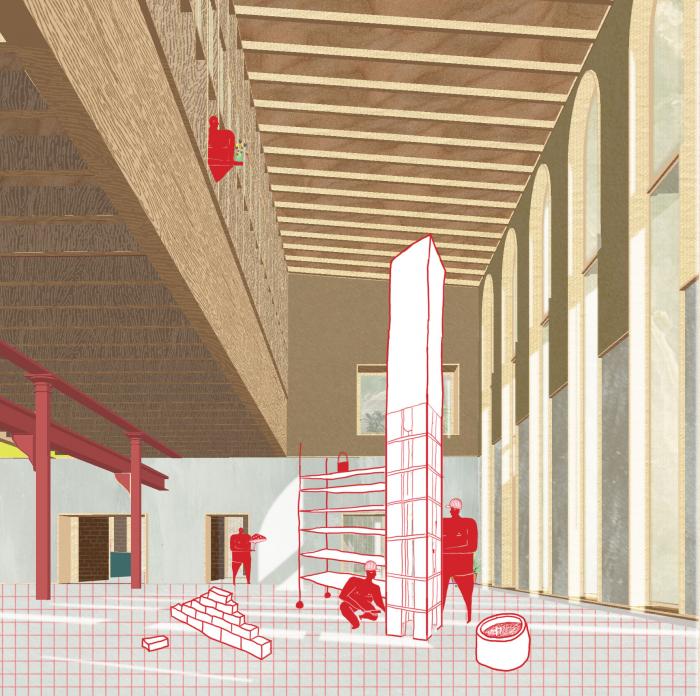

Secondly, the « Macro-Factory » is thought as an experimenting room, where could be built scaled-one prototypes with living materials. This infrastructure is part of a vast regional or international network of Schools of Architecture, from Belgium, France, Germany and Netherlands. This basin requires an ambitious infrastructure in order to be able to carry out a european educational project, capable of structuring everyone in living construction, integrating all actors, in a logic of exemplary circularity.

The two « Factories » are linked by the « Forum », a new building inserted between the two existing buildings, is the reception place, for the daily or the weekly public, thanks to its dormitories and facilities

Please highlight how the concept/idea can be exemplary in this context

The « Architecture Center for regenerative materials » is thought as an eco-system, a place to experiment, raise awareness and produce around the regenerative materials. We propose, as a first step, to substitute industrial materials by, as much as possible, natural materials, which require less carbon during their production.

The materials produced in the "Micro-Factory" are ready-to-use bricks or insulating panels. All the interior insulation of the "Architecture Center for regenerative materials" is carried out with its panels, produced in the basements of the building, in a logic of short circuits and circularity. We have worked on thermal correctors based on plant fibers and mycelium, plastered with earth to improve hygrothermal comfort, without enveloping the entire building. For the new building, all the insulation is made with the same hemp-mycelium resource, filling in wooden frames. This system could be generalized and we could see buildings under renovation producing their own “growing” insulation.

To concrete-plastic-ventilation machine, we wish to oppose construction in wood-earth-hemp-mycelium… and natural ventilation… One of the main qualities of organic and geo-sourced materials is its reversibility. Beyond their carbon impact upstream, these materials can return to the earth without polluting. An earth plaster can be reused endlessly without chemical stabilizer. Likewise, the mycelium-based materials could, the fungus being asleep in a controlled manner, be reactivated to produce new shoots on new supports, with the same reference material. All these materials are analyzed and processed within the "Micro-Factory". In addition, all materials are tested in the "Macro-Factory", a large open experimentation hall for training on living materials. This is accompanied by a material library integrated into the "Micro-Factory", which presents the joint results of the research carried out in the laboratory and the experiments built in the "Macro-Factory".

Please highlight how the concept/idea can be exemplary in this context

We must question the social and political function of the architect and of Architecture. The architect must take responsibility and be aware of the weight of the prescription. Prescription is political. The choice of materials we use is political. Each line designed integrates a production chain, from extraction to implementation, including transport. This return to an awareness of our responsibility should not obscure our other responsibilities to the history of our discipline and its users.

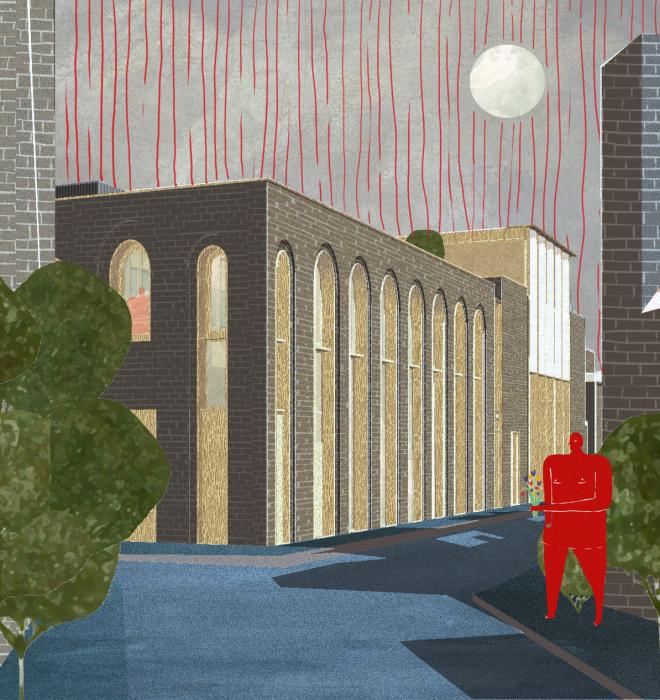

There is one major gesture in the project that structures the whole building, making the link, and the place. Originally divided into three distinct entities, with perpendicular accesses to the main street, the building, which retains this tripartite organisation, is now crossed along its entire length by a large programmatic band, integrating the classrooms for the experimentation hall, the refectory for the Forum, and the laboratory rooms for the production part. This large band is what structures the whole, giving coherence from the parts to the whole, while guaranteeing the quality of the spaces along the main facades, favouring good heights and a consequent contribution of natural light.

In addition, to the environmental and comfort qualities brought by the natural materials mentioned above, whose presence is soothing, all the wooden structures are carefully chalked out, playing with the hierarchy between primary and secondary elements, between the fall of beams on columns, wooden frames that underline and lighten the bays and suspended volumes. The living materials, load-bearing wood or filling materials, mineral for the earth, plant fiber for the mycelium, bring their variety of grains and shades, whose visual quality will complete the above-mentioned thermal comfort.

Please highlight how the concept/idea can be exemplary in this context

We have already discussed the responsibility of the architect and the impact of a line, which integrates a whole production chain. We have already discussed the impact of the materials to be extracted, processed and used. In fact, in addition to the production of hemp and the agricultural policy that goes with it, already mentioned, there are the skills and know-how related to the other resources used, from the least processed to the most developed in terms of technological skills, such as the production of panels based on mycelium. This should make it possible to guarantee a quality local workforce, a guarantee of the sustainability and strategic independence of our production methods. In this way, committing to natural resources also means thinking about the development of resilient territories, based on local resources and employment.

Moreover, in addition to the quantitative aspect of employment, there is a qualitative aspect. Indeed, working for a more sustainable development of production methods around known and locally understandable materials gives meaning to human action, rooted in a real and symbolic place. In the same way, the materials used are healthy for those who live and those who build, unlike concrete, which is responsible for numerous illnesses among workers.

Let's not fall into an idealization of the local. It is also linked to more global and universal issues. Indeed, our project is conceived as a European infrastructure, for these two aspects. The first part, productive, with the need of hemp, articulates agricultural policies to be thought on a transnational basin. The second part, educational, is a place of exchange and learning for all Europeans, no matter their gender, race or social origin.

Please highlight how this approach can be exemplary

The architecture center for regenerative material is a place with local and natural content and container. As a « content », it is a place of production of natural insulating materials, which works towards the valorisation of the excessively available land in Brussels, to limit demolitions as much as possible, by using empty platforms, and the thermal renovation of buildings, with natural materials, not coming from the petrochemical sector.

Moreover, it is a place of awareness for the general public, as well as for professionals. The infrastructure is designed on a European scale and will help to train the designers and decision-makers of tomorrow.

As a « container », the whole building is built with natural materials, by and for local jobs. Working for a holistic system, with all parts forming a coherent whole, the project is in line with all aspects of sustainable development, on the environmental aspects, by proposing real answers to the technical-productive problems of construction, by reducing emissions and the carbon impact of materials during production, by minimising transport, by lowering energy requirements for operation thanks to its thermal response, for the renovation of existing buildings and for new buildings, by drastically reducing the end-of-life impact; social, through the use of local, healthy jobs throughout the production chain; economic, through the spin-offs generated by the previous point.

All of this is done without the sacrifice of the attention to detail required by such an ambitious scale of infrastructure, the name of which will not reflect the care normally taken in such a programme. It will be an architecturally magnified programme to address local issues that can be transposed to a European scale.

Taken separately, all the aspects mentioned are already partly known, although marginal, in relation to the quantities mentioned in the construction sector as a whole. This known aspect, although partial, bears the reassuring and necessary part of the good functionality of the proposed program.

However, there are two major innovations and a major articulation that is taking place. Firstly, on the scale of the material. Indeed, in order to reduce the carbon impact of the construction sector, we first of all evoked the need to work around a plant material, the mycelium, which, rather than starting from a quantity X extracted in which a small part of the material will be usable, then transformed and transported, this one functions by proliferation, by increasing the material. There is a lever here on the raw material and its ability to generate more without much input.

In addition to the material, which alone is not sufficient, we propose to approach it as a building material. Indeed, in addition to the reduction of emissions induced in its production, mycelium will be used to generate insulating panels, necessary for the thermal renovation of buildings, without materials from petrochemicals, that can’t be a sustainable answer if we talk about the all chain of production.

Finally, this building material must find a place for its production. Thus, rather than the perpetual recourse to demolition or to the policy of the empty chair, we propose to use an available resource, the empty floors, 1,6millions m2 in Brussels in 2016, to transform it into a place of in-situ production, within the city itself.

In this way, those answers include a large part of innovation, from the material, a growing plant material, zero carbon, to the building material, a growing insulating panel, through the places and conditions of its production, transforming empty floors into producing eco-system, within the city itself, which will therefore become the object AND the subject.

Firstly, all the reflections carried out within the framework of the competition, and proposed for this prize, are the fruit of experimental research carried out within our association. With this research, we were able to understand the logic inherent in mycelium, to define certain body-binding recipes and to start producing some furniture elements. From these, we were able to start imagining changes of scale, from furniture to living space, and to widen the stakes. With our knowledge of the material, we were able to start thinking about the place it could take in a form of carbon-free production of construction and to think of a new form of architecture, living architecture.

However, apart from the positive aspects, we also saw the current limits of our mode of production. Requiring a change of scale, we must now work to structure the sector. This requires an increased knowledge of the material, linking architects, engineers and micro-biologists in order to think of the entire production chain, from the laboratory to the wall, via the incubator, where the material grows. This must have a place, and means. This place could be the site, the CIVA in Brussels, and the programme we propose. Based on our knowledge of this material and its limits, the proposed programme is concrete, feasible and could be directly operative.

Divided into three buildings, the work on the existing building could be phased in three parts as well. Firstly, we could renovate/convert the most recent building, to the east of the site, and the surrounding area/accesses of the plot, so that the building could directly accommodate the laboratory and production rooms in the basement. Secondly, while the laboratory is already in operation and the first panels are being produced, we could convert the old building to the west of the site into a test hall. Finally, once the "programmatic skeleton" has been completed, the central building could be built to house the entrance, refectory and dormitories.

With our association, we have been working on these issues for several years. In the crowd of ideas proposed in competitions, the money generated by the prize could be invested in several forms:

First of all, we hope that the enthusiasm generated by the Bauhaus Prize, in the midst of the european Architecture prize Europan, will allow us to concretise the proposals mentioned above, in order to give impetus to new dynamics within the Brussels metropolis, which could potentially form a system and be replicated within other metropolitan territories.

On the one hand, this would allow us to finance more experiments in order to define stable recipes for the material itself, i.e. the relationship between binder and plant body. From this, we could also get in touch with laboratories within Universities to be able to do laboratory tests in order to obtain the necessary certifications for the materials tested and then produced. This would allow us to be part of a wider research network and to advance scientific knowledge.

On the other hand, in addition to the experimental and scientific aspect, the money generated could allow us to stage an exhibition and/or events around the issues raised by the decarbonation of the construction sector. By focusing on the mycelium, explaining the logic inherent to the material and the transposition to issues at the scale of construction, we could raise public awareness of the issues and opportunities of sustainable construction.

Finally, in the same logic, we are thinking of writing a book, which could be the synthesis and/or the further development of the previous points.

@Dalon, 2022

Content licensed to the European Union.